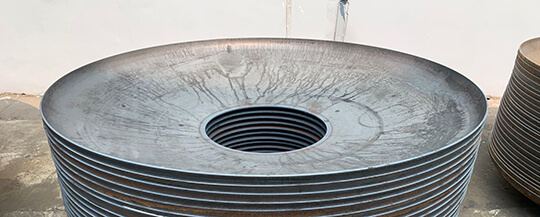

The head adopts the method of integral forming after welding of the panel. Determine the unfolded size of the elliptical head blank according to the formula. Due to the limitation of the width of the fixed-length board, the two boards are spliced, and the seam is selected in the middle of the head. In order to ensure the quality of the head assembly, the splicing longitudinal seam groove adopts the form of edge planing machine processing. The groove must be smooth. Splicing and pairing, pay attention to the amount of right and wrong side when pairing. Weld according to the requirements of the welding process. After welding, the inner surface of the joint and the outer surface of the joint weld that affect the forming quality are polished to be flush with the base metal. The spliced welds are qualified by 100% RT and 100% PT non-destructive testing. The outsourcing professional head manufacturer conducts cold stamping forming in accordance with the provisions of GB/T25198-2010 "Pressure Vessel Head", and conducts inspection records of the surface quality, geometric size and geometric shape of the head, and forms a report. Re-inspect the relevant dimensions after returning to the factory, and perform a 100% RT re-test on the seam from the arc transition section to the straight edge section after forming. The purpose is to maximize the stress concentration in this R zone, and to control the quality of whether there are cracks after the weld is stretched due to the forming process. Finally, machine the straight-edge end face, center hole and groove on the CNC vertical lathe, and locate and scribe each pipe hole and groove.