In industrial applications, clad plate of pressure industry still choose the traditional explosive clad plate production process:

First:Pressure vessels, head manufacturers in the design institute requirements for using of composite plate. Second: the pressure vessel committee in 1994 had the document to designate the explosive composite plate as the pressure vessel.

Today, with the rapid development of industrial production, the traditional explosive clad plate are far from meeting the needs of the current industrial production development due to the limitation of production conditions. The more advanced hot-rolled clad plate in foreign countries have gradually occupied in China since 2000. Greater market share.

Hot rolled clad plate is not the clad which we thought the binding rate of 98%, 99% 10 years ago, but the same as the explosion plate 100%, and the production speed is faster, the environmental protection is more powerful, the shear strength in 400MPA, bending stretch in 340-490mpa, can be completely used in the pressure equipment industry.

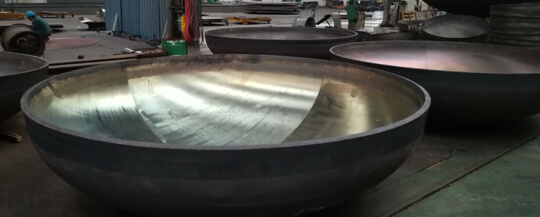

The advantages of using a rolled clad plate to press the head are: low price, fast speed, high recombination rate, and longevity. The method for head manufacturing of High-strength austenitic nickel-iron-chromium alloy and austenitic stainless steel composite plate, medium-temperature heat forming, and solid solution treatment after heat forming; The conditions of the pressing process: the temperature of the empty furnace is increased to 1000±75℃, and the head circular plate is put into the furnace to ensure that the temperature of the head circular plate≥800℃, and it is heated to 1100℃±15℃with the furnace after being charged. After 2~4h, the furnace is hot pressed, the number of hot pressing≥2 times, and the temperature of the head is measured at any time during the pressing process. When the temperature is lower than 850℃, the furnace is reheated, and the final pressure can’t be lower than 850℃. The invention adopts a process of radial fine polishing before the head of composite plate is pressed, medium temperature hot forming, and then make solid solution processing.

Stainless steel clad plate is a composite plate made of carbon steel base layer and stainless steel through special manufacturing process (patented technology). Its main characteristic is that the carbon steel and the stainless steel form the firm metallurgical bond. It can carry on the hot pressing, the cold bending, the cutting, the welding and so on various processing and has the good technological performance. The base material of stainless steel clad plate can use Q235B, Q345B, Q245R, Q345R and other kinds of ordinary carbon steel or special steel. Materials and thickness can be freely combined to meet the needs of different users.

Stainless steel clad plate has been widely used in petroleum, chemical industry, salt industry, food and medicine, water conservancy and electric power industry. As a resource-saving product, stainless steel clad plate can reduce the consumption of precious metal and greatly reduce the construction cost. Stainless steel clad plate has the characteristics of various carbon steel and stainless steel, achieving the perfect combination of low cost and high performance, with its excellent performance and price ratio welcomed by users, has a broad market prospect, has good social and economic benefits.